12 Most Common Mistakes When Specifying Circuit Protection For Equipment

It's only a circuit breaker. Yet there is enough complexity and confusion when it comes to specifying circuit protection that many engineers are designing equipment with too little or too much protection. Under protected circuits leave equipment vulnerable to damaging electrical surges. Over protected circuits add cost and can lead to nuisance tripping. Like Goldilocks and the Three Bears, the goal is to specify circuit protection that is "just right".

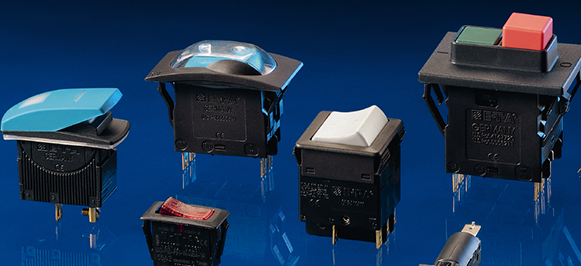

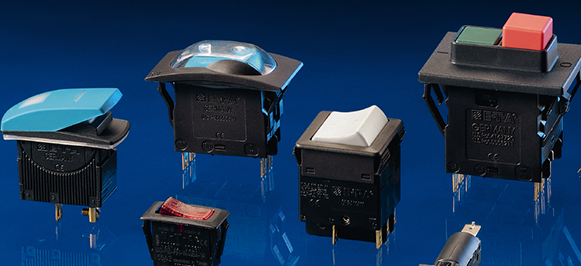

As a leading manufacturer of circuit breakers for more than 50 years, E-T-A has helped countless engineers navigate the specification process. Though this experience, we have encountered many misconceptions, and we have selected the 12 most common pitfalls for this white paper. It is our hope that, by sharing our expertise, you will avoid these mistakes and protect your designs with "just right" circuit protection.

1. Specifying the wrong circuit breaker type for the application

The number one mistake made is specifying the wrong circuit breaker technology for the application. There are four choices of circuit breaker technology: thermal, magnetic, thermal-magnetic and high performance. Each has a different trip profile in relation to time and current, and each has distinct mechanical characteristics.