The Dirty Dozen: Common Generator Protection Mistakes & How to Avoid Them

Why Smarter Circuit Protection Is the Key to Generator Reliability

Generators are critical for modern infrastructure. Whether it's powering essential systems in hospitals, maintaining uptime at construction sites or enabling mobile operations in mining and oil fields, generators are at the heart of backup and mobile power strategies. Yet, despite their importance, one crucial aspect is often overlooked: circuit protection.

At E-T-A, we specialize in circuit protection solutions and have seen the cost of poor decisions in generator systems—equipment failures, extended downtimes, costly repairs and even safety hazards. Many of these risks stem from avoidable mistakes in specifying overcurrent protection. In this white paper, we revisit The Dirty Dozen: Common Generator Protection Mistakes & How to Avoid Them

Power Without Interruption Starts Here

Generators operate in demanding environments where every component counts. Poor circuit protection choices are among the leading causes of system downtime and performance issues. Here’s what to watch out for—and how to avoid it.

1. Specifying the wrong circuit breaker type for the application

The number one mistake made is specifying the wrong circuit breaker technology for the application. There are four choices of circuit breaker type: thermal, magnetic, thermal-magnetic and high performance. Each has a different trip profile in relation to time and current, and each has distinct mechanical characteristics.

Magnetic Circuit Breakers

Magnetic circuit breakers operate via a solenoid, and trip nearly instantly as soon as the threshold current has been reached. This type is appropriate for printed circuit board applications and impulse disconnection in control applications. Often, a magnetic circuit breaker is combined with a hydraulic delay to make it tolerant of current surges. Preferably, the circuit breaker is mounted in a horizontal position to prevent gravity from influencing the movement of the solenoid. If mounted in a non-horizontal position, derating may be needed.

Thermal circuit breakers

Thermal circuit breakers incorporate a heat-responsive bimetal strip or disk. This type has a slower characteristic curve that discriminates between safe temporary surges and prolonged overloads. It is appropriate for machinery or vehicles where high current in-rushes accompany the start of electric motors, transformers and solenoids.

Thermal-Magnetic circuit breakers

Thermal-magnetic circuit breakers combine the benefits of a thermal and magnetic circuit breaker: a delay that avoids nuisance tripping caused by normal inrush current, and fast response at high currents. High overcurrents cause the solenoid to trigger the release mechanism rapidly, while the thermal mechanism responds to prolonged low value overloads. They have a characteristic two-step trip profile that provides fast short-circuit protection of expensive electrical systems while minimizing the risk of disrupted system operation.

High Performance Circuit Breakers

Where reliable operation under adverse conditions is required, high performance circuit breakers provide high interrupting capacity and excellent environmental specifications. Typically these circuit breakers are specifically designed for aerospace, defense and similar heavy-duty applications where extreme vibration, mechanical shock and other conditions are present where circuit breaker performance is absolutely critical. For high performance applications, thermal circuit breakers have a compensating element that eliminates sensitivity to ambient temperature.

Many engineers seek specification assistance from the support desks of circuit breaker manufacturers. However, be wary of advice from manufacturers who make only one type of circuit breaker. E-T-A Circuit Breakers has expertise in all circuit breaker technologies and its applications engineers will recommend the right type of circuit breaker, regardless of technology or type.

2. Specifying too high a rating in an effort to avoid nuisance tripping caused by in-rush or transient currents

Most engineers are concerned about nuisance tripping and as they should be. Therefore, they often specify a breaker rated much higher than they should be. Part of the reason is confusion between fuses and circuit breakers. Engineers are used to oversizing fuses as a way to prevent nuisance tripping. However, there is no need to oversize a circuit breaker.

Unlike a fuse rating, a circuit breaker amperage rating will tell you what the normal operating amperage it will hold consistently and within normal ambient room temperatures. Thus, a 10A circuit breaker will maintain a 10A current without nuisance tripping. In fact, a typical 4 amp thermal circuit breaker will tolerate an inrush current of 10 amps for a very short duration without tripping.

Often times, nuisance tripping is caused by in-rush currents associated with certain electrical components - primarily motors, transformers, solenoids and big capacitors. In such cases, the designer needs to specify a circuit breaker that has a delay. Thermal circuit breakers have a natural delay, and magnetic circuit breakers can have added hydraulic delays. Match the delay to the duration of the expected in-rush currents.

3. Failure to provide spacing in design

It is important to maintain recommended minimum spacing requirements between non-temperature-compensated thermal circuit breakers. A mere 1 mm spacing between breakers is all that is required. Without this tiny thermal gap, the circuit breakers can potentially heat up and increase the sensitivity of the bimetal trip mechanism. If these circuit breakers are mounted within the same proximity, you may consider spacing or possibly derating if ambient is significantly increased.

4. Over specifying or ambiguously specifying the degree of protection

Terms such as drip-proof, ignition protection, water splash protection and dust proof are common requirements, but may be misleading unless standard definitions are applied. When specifying, use the established standards as a measure, such as EN 60529/IEC 529 which defines the degree of protection of Electrical Equipment. Using these standards, decide which protection is correct for the application.

For example, ignition protection makes sense if the breaker is installed in the engine compartment of a boat, but is not needed if installed in the boat panel. A combination switch-breaker installed in medical equipment might need water splash protection rating, but it probably does not need a rating for continuous immersion in water. Options for meeting these requirements are available and typically add costs, but only recommended when truly necessary.

5. Selecting the Correct Actuation

Circuit breakers are reset manually by means of an actuator. There are many types of circuit breaker actuators, including press-to-reset, push-pull, push-push, rocker, toggle, baton and press-to-reset with manual release. The actuator type is more than a cosmetic consideration. For example, critical applications usually call for push-pull style actuators, because they are the most resistant to accidental actuation. The type of actuator you select will be determined by the location of the circuit breaker, the need for illumination, the need for human operator safety or convenience , and the consequences of accidental engagement.

6. Failure to consider using circuit breakers as on/off switches Many

Many circuit breakers are designed to be both a breaker and on/off switch. The advantages of a combination device are a reduction in components, less consumption of panel space, reduced wiring and increased protection over ordinary switches.

7. Specifying the wrong type of terminal

Circuit breakers with plug-in style quick connect terminals simplify installation and replacement. Quick connect terminals may be used for circuit breakers rated up to 25 amps. Screw terminal connections are more secure and suited for high current and high-vibration environments.

8. Specifying a fuse when a circuit breaker would be better

How can you be sure the fuse you specify will open or trip accordingly to an overload condition?Although fuses provide inexpensive circuit protection, the cost savings should be weighed against the low total cost of ownership of circuit breakers. Foremost, circuit breakers can be quickly reset, enabling the circuit to be restored with a minimum of downtime. In addition, there is no assurance that a replacement fuse will be of the proper rating. If a fuse is replaced by a higher rated fuse, overheating and catastrophic equipment failure may occur.

Circuit breaker performance is relatively stable over time, but as fuses age, their trip characteristics change. This may lead to nuisance tripping and increased downtime.

Circuit breakers offer designers more options than do fuses. An auxiliary contact may be added that can communicate an alarm condition to an LED indicator or process software. In addition, a circuit breaker can be combined with a switch, saving space and adding overload protection. Remote trip is another option available with circuit protection as well as under-voltage protection, but not with fuses.

Furthermore, unlike fuses, circuit breakers have a variety of types and trip profiles, and therefore can be more precisely matched to loads and various environments.

Finally, fuses cannot be tested without destroying them. How can you be sure the fuse you specify will open or trip accordingly to an overload condition?

9. Specifying the wrong type of circuit breaker for a high vibration environment

Typically, the trigger of a magnetic circuit breaker is a hinged metal armature that closes in response to the movement of a magnetic coil. This design makes magnetic circuit breakers (and magnetic-hydraulic circuit breakers) particularly vulnerable to vibration, which can cause the armature to close prematurely.

In contrast, a typical thermal circuit breaker is comprised of a thermal actuator and a mechanical latch and are therefore highly tolerant of shock and vibration.

If a magnetic circuit breaker is the best type for the application, its vibration resistance can be improved by using a push-pull style actuator. This type of actuator has a latching design.

10. Failure to derate

As a rule of thumb, the circuit breaker should be rated for 100% of the load. However, some applications require a circuit breaker to operate continuously in either high or low temperatures. In these cases, follow the manufacturer's guidelines for derating. For example, an application calling for 10A protection requires a 12A rated thermal circuit breaker when it is operated at 50° C.

11. Derating when it is not necessary

The performance of a thermal circuit breaker is sensitive to fluctuations in ambient temperature. It will trip at higher amperage in a cold environment, and it will trip at a lower amperage in a hot environment.

One common mistake is to assume that derating is necessary for thermal circuit breakers in environments that experience rises in ambient temperature. Actually, the performance of a thermal circuit breaker tracks the performance needs of the system, assuming it is exposed to the same heat source. For example, motor windings need more protection from overheating at 90° C than the same windings need at 20° C. A cold motor requires more in-rush current to get started, and therefore a longer delay is advantageous on a cold day.

Another misconception is that magnetic-hydraulic style circuit breakers are immune to performance changes in rising ambient temperatures. On the contrary, these circuit breakers contain a dashpot with a liquid core that becomes more fluid at higher temperature, reducing the time of the hydraulic delay.

12. Over specifying interrupting capacity

Interrupting capacity is the maximum amperage a circuit breaker can safely interrupt. Circuit breaker manufacturers publish this specification along with the number of times the circuit breaker will perform this feat. For example, E-T-A publishes two types of interrupting capacity specifications. One is called Icn, or normal Interrupting Capacity. Icn is the highest current the circuit breaker can interrupt (three times minimum, per IEC934/ EN60934 PC2). Icn gives a rough idea of circuit breaker quality. The other specification is an AIC / amperage interrupt capacity which is the maximum current the breaker will disconnect and fail safe a minimum of 1 time.

To comply with various standards, engineers must specify circuit breakers with adequate interrupting capacity. Unfortunately, applying the appropriate standard may be confusing. For example, UL 489 requires interrupting capacity from 5000A and above. While perfectly appropriate for main power distribution applications, this standard has been perpetuated in other industries, where the short circuit rating, governed by circuit resistance, is much lower. The UL 1077 standard for supplementary protectors covers the short circuit test and lists the current at which the breaker was tested.

Although certain devices such as UL 489 molded case circuit breakers have higher interrupting capacities, they may not be well suited for lower current applications where precise overload protection and adequate short circuit protection is better provided by a UL 1077 supplementary protector.

The telecom industry is particularly prone to over specifying interrupting capacity because some vendors of circuit breakers for DC telecom equipment also market the same circuit breakers for AC power distribution. Although the potential supply of current seems high in telecom applications, the realistic amount of current available is actually far less, due to line loss. In most telecom applications, a circuit breaker with 2000A interrupting capacity is more than adequate.

Smarter Protection, Stronger Performance

Every generator system—from portable welders to industrial standby units—relies on circuit protection to stay safe, reliable, and compliant. Avoiding the dirty dozen mistakes doesn’t just save you time and money—it protects your brand, reputation, and your customer's trust.

Choosing the right circuit protection means:

Maximizing Uptime: Resettable breakers eliminate the need for constant maintenance and replacement.

Enhancing Safety: Immediate, reliable disconnection protects people and equipment from dangerous faults.

Reducing Costs: Fewer repairs, fewer replacements, and longer equipment life add up to major operational savings.

Optimizing Performance: Specialized breakers withstand inrush currents, extreme environments, and heavy-duty cycles.

Type 2-6500

Approvals

UL1077

Rated Voltage

AC 250 V (50/60 Hz), DC 28 V

Current Rating

from 0.1 A up to 10 A (up to 15 A upon request)

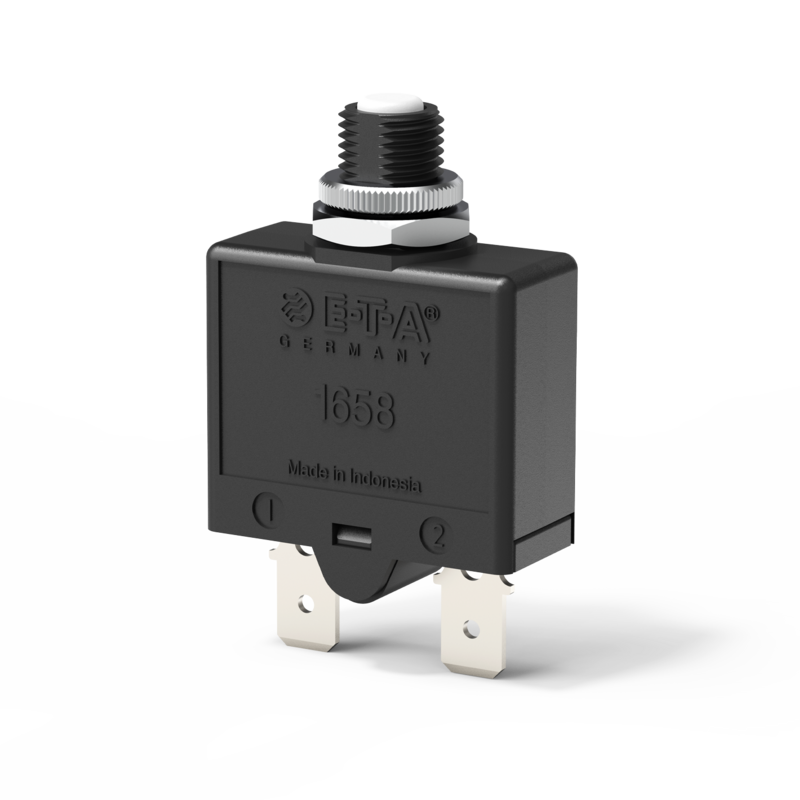

Type 1658

Approvals

VDE, UL1077

Rated Voltage

AC 240 V, DC 28 V

Current Rating

from 5 A up to 30 A

Type 2-5700

Approvals

VDE, CSA, UL1077, CCC

Rated Voltage

AC 250 V / DC 28 V / UL/CSA: DC50 V

Current Rating

from 0,05 A up to 25 A

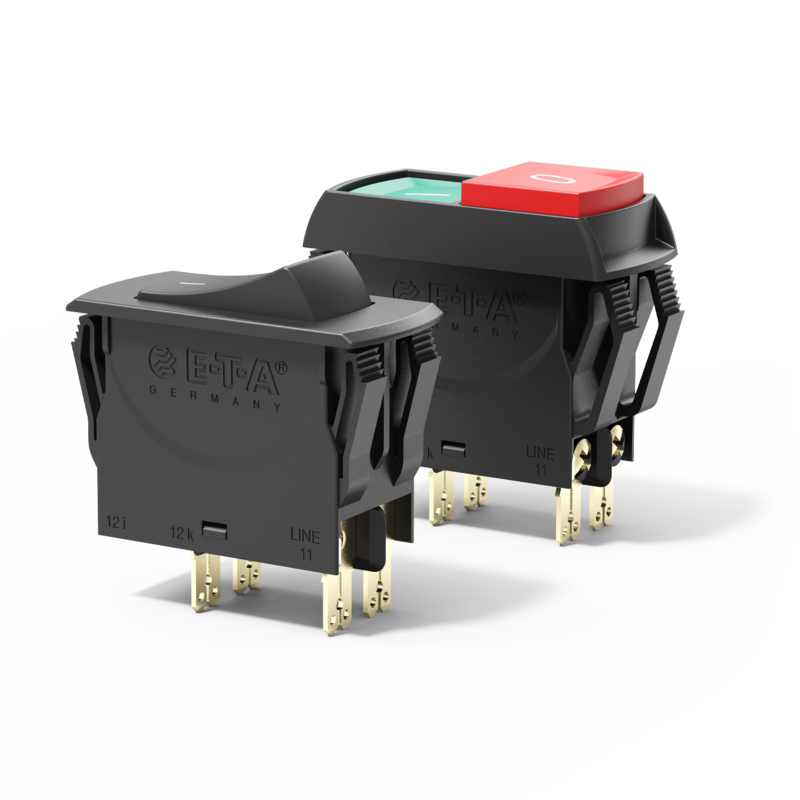

Type 3120-N

Approvals

VDE, UL, CSA, CCC, KC

Rated Voltage

AC 240 V, DC 50 V

AC 415 V upon request

Current Rating

from 0.1 A up to 20 A (up to 30 A to special order, single pole only)

Type 8335

Approvals

VDE (EN 60934), UL 1077, Ignition protected (UL 1077 + UL 1500), UL 489A, UL 489, CCC

Rated Voltage

AC 3 / 415 V

AC / 240 V (50/60 Hz)

DC / 80 V

Current Rating

from 1A up to 50A 1- and multipole

Type 4230-T

Approvals

UL1077, UL489

Rated Voltage

AC 480/Y277; DC 60/125V

Current Rating

from 1 A up to 63 A

Who Uses E-T-A?

Whether you’re manufacturing residential backup generators or engineering multi-megawatt industrial systems, E-T-A is your ideal partner.

Our solutions are perfect for:

Portable / Semi / Stationary Generators

OEMs and System Integrators in Oil & Gas, Mining, Construction, Welding

Residential Generator Brands

Engineers designing automation and backup systems

Hybrid / Inverter Generator Solutions

Request a free sample and discover how to optimize your generator systems.

Don’t wait for failure. Choose circuit protection built for today’s power challenges. Request a product sample or talk to one of our sales representatives to find the best solution for your generator application.

Request a sample today and test E-T-A’s circuit protection in your design!