Easy Integration Based on ISO 26262

All-in-One Electromechanical High Voltage Contactor for Electric Vehicles

Easy Integration Based on ISO 26262

All-in-One Electromechanical High Voltage Contactor for Electric Vehicles

Introducing E-T-A's electromechanical contactor designed specifically to protect the HV-battery in electric vehicles (EV).

Our HVB10 solution combines protection and switching functions in a single device, eliminating the need for HV fuses and reducing complexity. With autonomous short-circuit and overcurrent protection, our solution ensures unparalleled safety standards while offering the convenience of effortless resetting for minor overcurrents, enabling uninterrupted vehicle operation.

Join us in shaping the future of EV safety and efficiency with E-T-A's electromechanical contractor.

Interested in learning more about E-T-A's HVB10 High Voltage Contactor?

Complete the form below to schedule a meeting with Gary Hayes. You can also reach him at [email protected] or 612-867-3591.

Extend existing safety concepts

Electromechanical solution falls under "other technology" according to ISO 26262 making it easier to integrate into existing safety concepts.

Protect Vehicles with Proven technology

Electromechanical overcurrent and short circuit protection which can be tested and is failproof when applied correctly within the BMS.

Reduce Vehicle Service Costs

Diagnostic functions for open or closed contacts thanks to reliable, integrated mechanical auxiliary contact.

ADDITIONAL FEATURES

- Protecting and switching in one device. Integrated, autonomous short-circuit and overcurrent protection. In case of overload, the device trips by itself. A HV fuse is no longer necessary, so you reduce complexity.

- Overall, less installation space, as components including connection technology are replaced.

- No coordination effort between contactor and fuse. Safe "All in One" solution!

- No contamination by pyrotechnics. Air and creepage distances do not have to be extended. In addition, less handling effort! (Storage, production, aftersales, logistics especially air freight).

- Can be completely reset in the event of a slight overcurrent. The vehicle can drive to the workshop if necessary.

Savings

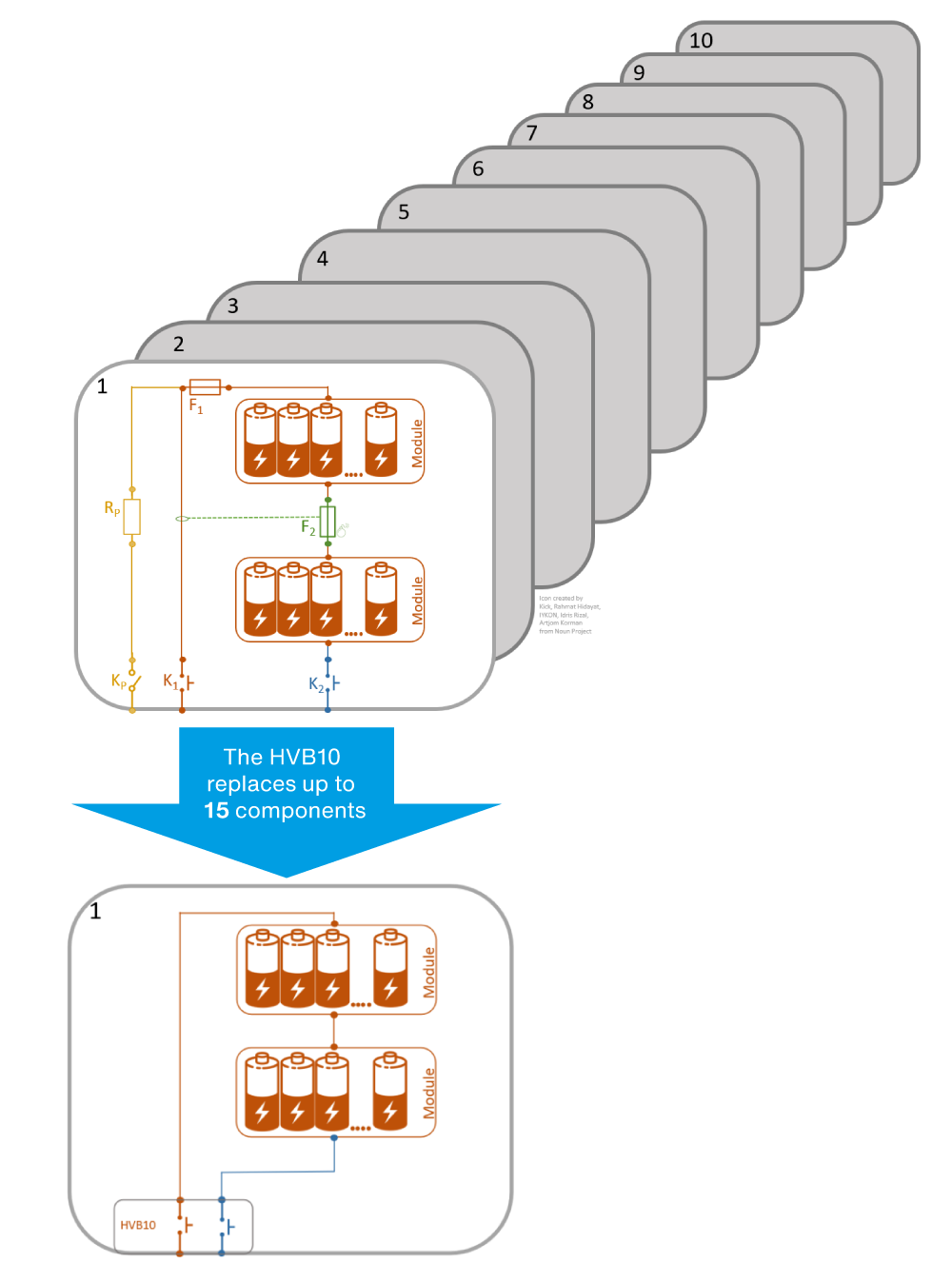

The HVB10 can save up to 15 components per battery pack:

- 2 x High Volt Relay

- 2 x PWM relay current saving modules

- 1 x Fuse

- 1 x Pyrofuse

- 2 x control lines (relay and pyrofuse)

- 2 x HV busbars

- 5 x connections between individual components

For a long-haul truck with 10 battery packs, 150 components can be replaced by 15 HVB10s.

Core Specifications

- 2-pole device (Switches + and - simultaneously)

- Rated voltage 850 V

- Continuous current approx. 340 A

- Max charge current approx. 680 A for 700 sec.

- Breaking capacity 24,000 A (one time only)

- Bidirectional - No preferred direction

- Mech. Lifetime 500,000 operations

- Electromechanical overcurrent protection

- Condition monitoring via mirror contact

- Protection class tbd. (Protected against external environmental influences by the battery housing)

- Installation space approx. (128 x 176 x 71) mm

- Weight approx. 2 kg

Interested in learning more about E-T-A's HVB10 High Voltage Contactor?

Complete the form below to schedule a meeting with Gary Hayes. You can also reach him at [email protected] or 612-867-3591.